APPLICATIONS

Hydronic floor heating is a good choice for large, open areas where people gather. It works well under cold flooring materials like marble, stone, slate, polished concrete, and all types of tiles. It can also be used under carpet and timber floors. The best time to install hydronic underfloor heating is during the initial construction of a home, but it can also be added during a renovation. If installing it during a renovation, you need to plan ahead—this type of heating adds thickness to the floor, which may affect the rest of the design. There are different installation methods depending on the floor type: In-screed or in-slab systems are used for hard surfaces like tile and concrete. Diffusion plates are used for timber floors with battens underneath.

INSTALLATION OVERVIEW

Installing a water-based (hydronic) underfloor heating system can be complicated because of how it’s designed and how it works. That’s why it’s important to hire a licensed professional to do the job. These systems are most commonly used in new buildings because they can be easily built into the concrete slab. However, they can also be added to existing homes if the floor has a screed layer that’s at least 50 mm thick (though 80 mm is better). Since this type of system raises the floor level, some people choose electric floor heating instead during renovations. In a hydronic system, water is heated to about 50°C and flows at low pressure through a system of pipes, valves, and controls. All these parts must work well together to warm the selected areas of the home efficiently.

HYDRONIC UNDERFLOOR HEATING ESSENTIALS

X Thermostats

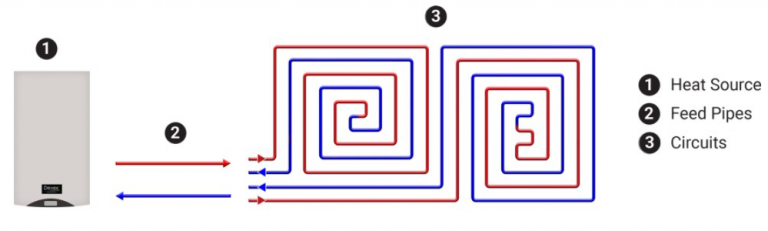

Thermostats A good thermostat helps your floor heating system work more efficiently. It lets you control the temperature in each room separately and set different heating schedules. Since hydronic heating is a central system, we suggest using non-programmable thermostats. These can connect to your smart home system and give you better control over temperature, zones, and timing. Heat Source – Gas Boiler We recommend using a gas boiler with natural gas as the main heat source. It costs less upfront than a heat pump, has similar running costs, and is more reliable than solar heating. If natural gas isn’t available at your home, a heat pump is a possible alternative depending on your budget. Feed Pipes Feed pipes carry hot water from the boiler to the manifolds. They can be installed in different ways depending on your building—under the steel mesh, through the wall, or across the ceiling. If hidden in concrete or behind walls, we use flexible plastic (PEX) pipes. If the pipes are visible, we use copper pipes for a neater finish, although they take longer to install. All pipes are insulated to prevent heat loss. PEX pipes go inside a conduit that creates an insulating air gap (like double-glazed windows). Copper pipes are wrapped in thick insulation. Manifolds Manifolds are control centers where all the pipe circuits connect. They distribute hot water to different areas and regulate the flow using small valves called actuators, which are controlled by floor thermostats. In mixed systems (with both radiators and underfloor heating), manifolds can include a mixing valve that blends cooler return water with hot water to reduce the temperature for the floor heating (since it runs at 50°C, while radiators run at 80°C). XPS Insulation Sheets XPS insulation sheets are placed under the heating pipes to prevent heat from escaping downward. This helps the floor heat up faster. Standard sheets are 25mm thick, suitable for 16mm pipes, and have an R-value of 0.89. Larger options are 30mm thick (R=1.07) and 50mm thick (R=1.78). Each sheet covers about 1.44 m² and helps improve energy efficiency. Diffusion Plates These are used with battened timber floors. The plates are placed on top of the battens and just below the floorboards, helping heat the floor quickly. Quick Heat System This system is great for floating timber floors. It combines diffusion plates with insulation underneath to stop heat from escaping downward, making the system faster and more efficient.